Measurement during normal turbine operation

With the ROMEG measurement method, operators have the possibility to measure their wind farm swiftly and without interrupting operations.

Regular checking of the rotor geometry

Regular inspection of the rotor geometry ensures that the wind turbines run without aerodynamic losses and that no additional loads caused by the rotor are introduced into the drive train.

The occurrence of aerodynamic and mass imbalances can lead to considerable economic losses caused by yield loss and increased wear.

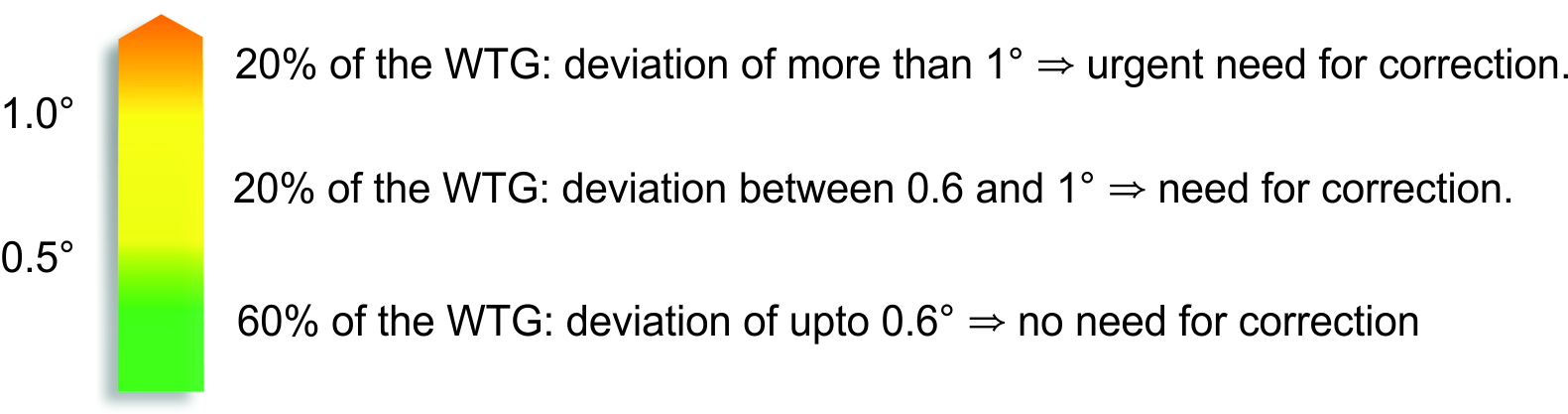

Measurements on more than 2500 wind turbines have led to the following result, which clearly shows the necessity of regular inspections.

Increased noise emission

Incorrectly adjusted blade angles also cause increased noise emissions, which can lead to complaints from residents and, possibly, to the temporary shutdown of the turbines.

Surveying as a service

windcomp GmbH offers operators the measurement of their turbines as a service. Talk to our experts and ask for a non-binding offer.

We also offer framework contracts for regular measurements of wind turbines in Germay and abroad.